4 Flush Joint Casing Specs

VAM® FJLTM (Flush Joint Liner) is a 100% inside and outside flush integral connection providing maximum clearance with optimum strength for liners, moderate depth casing, and tight-hole tubing strings.

- Available in sizes from 2 3 /8″ to 11 7/8″

- Yield strengths from 80 ksi to 140 ksi

- Standard, alternative and special drifts

- Carbon, Martensitic stainless steel (13%Cr & Super 13%Cr) and Nickel base Alloys.

We manufacture Flush Joint Casing as per BS,IS,DCDMA,CDDA standard.We use cold Drawn Seamless Steel Tubes of SAE -1040, SAE -1541,SAE 4130 steel Tube as per customer requirement.We manufacture this Flush Joint Casing on CNC machine to achive high accuracy and smooth Interchangebility of Thread. Surepipe’s Excelcasing-SFJ (Sharpe Flush Joint) is a premium, rugged steel casing/tubing connection with a shallow taper especially designed for thin wall steel pipe. Excelcasing-SFJ has proven itself in the Coal Bed Methane (CBM) industry with over 1.5 million metres since 2008, and embodies the core aspects of the Surepipe brand. Premium quality, precision threaded & over-specced for. SEAL-LOCK Semi Flush is an integral casing connection that utilized the latest in Finite Element Analysis and physical testing technology during its development. The design has multiple metal-to-metal seals; a close tolerance hooked thread form and an integrated torque shoulder that. The casing pipe shall also meet ASTM D2665. To assure easy make up, the PVC monitor pipe and screen must be threaded to the ASTM F480-90 specification with O-ring groove turned in the male thread. Titan maintains an extensive inventory of flush joint threaded PVC well casing and screen used for groundwater monitoring, remediation and dewatering. 2015 Casing Reference Tables World Oil®/JANUARY 2015 C–109 Dimension nomenclature D = Casing nominal OD of tube, in. W = Casing weight, lb/ft d = ID (drift), in.

- Drilling, production and contingency liners

- Moderate depth production casing /slim hole designs

- Tiebacks in medium sizes

- Tight hole tubing strings in small sizes.

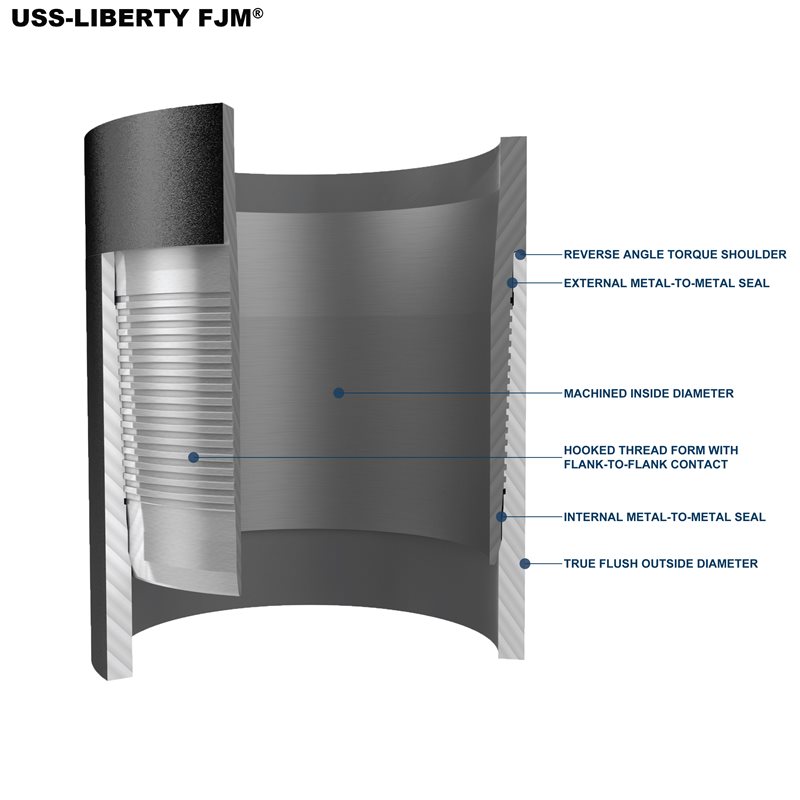

- Integral Flush Design. The O.D. and I.D. are 100% flush (there is no upset). The I.D. is bored and recess-free for smooth, efficient flow. The O.D. is turned to tight tolerances.

- Multiple Seal System. This multiple seal arrangement ensures gas-tight sealing integrity to 100% of the rated burst and collapse of the pipe body.

- Interference Tapered Thread. Thread load flank has a 15° reverse angle to resist jump out. Thread stabbing flank has a 45° angle for fast, trouble-free make-up.

- In order to provide optimum strength, the VAM® FJL™ is designed for 65% to 70% efficiency under tension in medium wall thickness.

- The design of VAM® FJL™ exhibits an exceptional bending resistance for a connection of this class.

- Excellent gas tightness.

5.5 Casing Specs

- Maximum clearance (100% flush)

- Easy to use and repair

- Only slight pin end swaging is needed for machining threads.